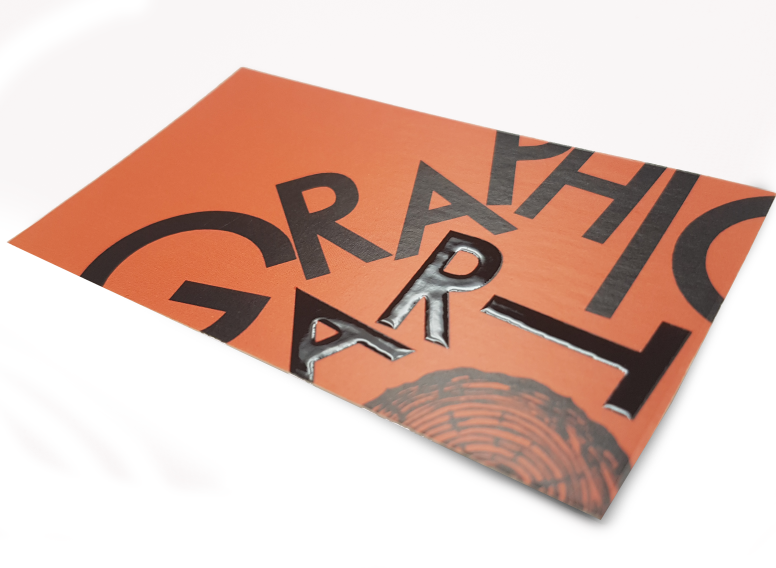

Spot UV Greeting Card

Matte Lamination + Spot UV

Spot UV greeting cards have finally arrived! Take the beautiful look and feel of uv spot gloss and let them transform your clients’ custom greeting cards with their clear, quality spot coating.

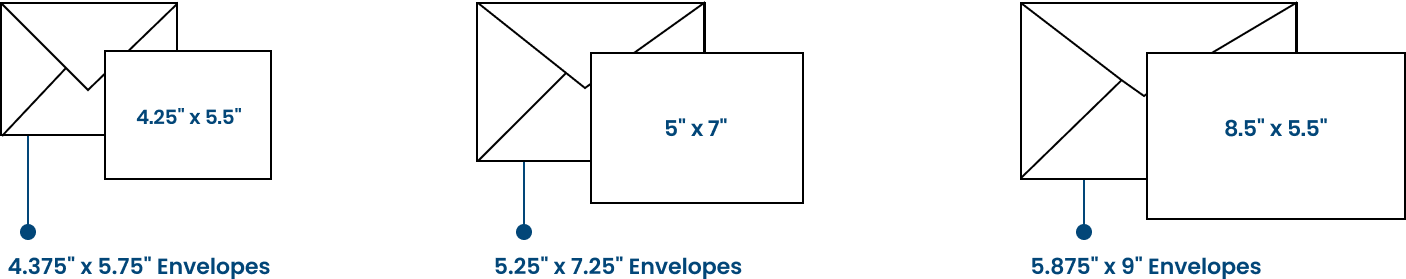

Envelope

Below are the envelope sizes for each of our standard greeting card sizes. Please note that any custom size greeting cards will not be a perfect fit with our standard envelopes. These envelopes will not be printed (white only). For printed envelopes, please order here.

14pt + 2pt Laminated Stock

Spot UV coated greeting cards are matte laminated greeting cards with clear spot gloss on top. The spot uv printing is a perfect contrast against the silk lamination that covers the rest of these custom greeting cards.

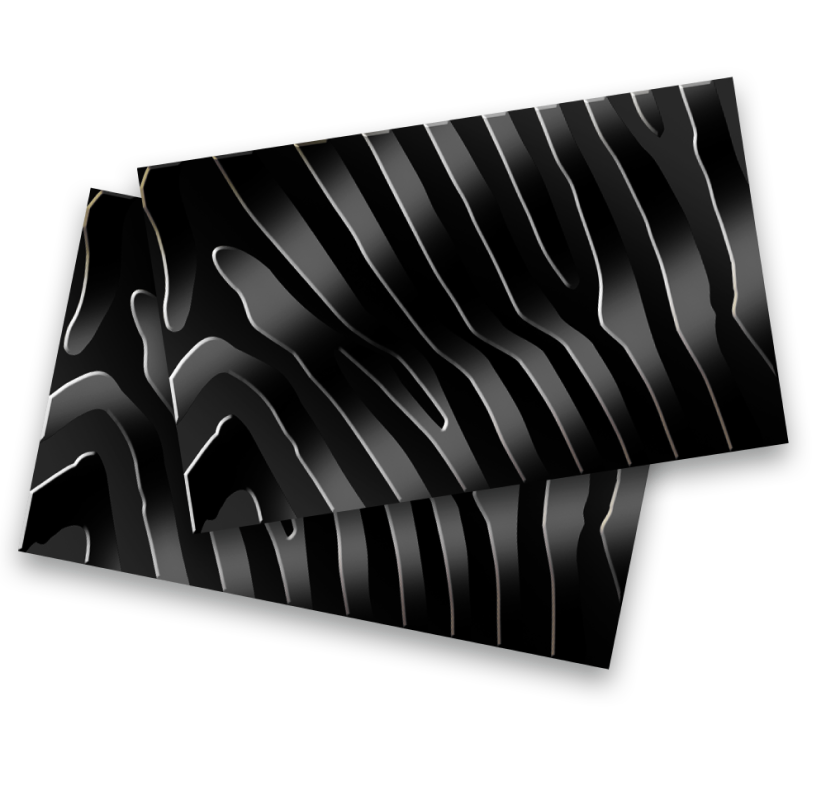

Clear Spot UV Printing

Our slightly raised spot UV printing make these custom greeting cards especially suitable for designs with dark backgrounds. This helps the spot uv stand out both visually and physically.

Raised Spot UV Greeting Cards

Your customers can now enjoy the tactile features of our classic spot gloss printing on their new spot UV greeting cards. When used on dark backgrounds, the spot UV printing stands our both visually and physically.

Folded Artworks (Greeting Cards, Folded Business Cards, etc.)

| Special Instructions | Please submit two PDF files: Art cannot be extended to cutting edges, otherwise there is a high possibility for the varnish to peel off (there should be at least 5mm of free-varnish area around cutting edges). Failing to do so will result into delays and/or creating product that is not as per expectation. Spot UV accuracy Positioning of the spot UV cannot be 100% guaranteed. Please note that there may be a shift of approximately 1/16" in the spot UV position on the printed product. |

Step 1

Ensure the file matches the product's required dimensions. Ensure that the artwork is created in CMYK 300 dpi with 1/16 inch bleeds on all sides.

Step 2

Make sure that all images are embedded, and that all the text is outlined.

Step 3

Export all files into PDF format with bleeds.

How to Prepare Your Files

Download Setup Guide

Get It NowHow to set up multi-page files properly

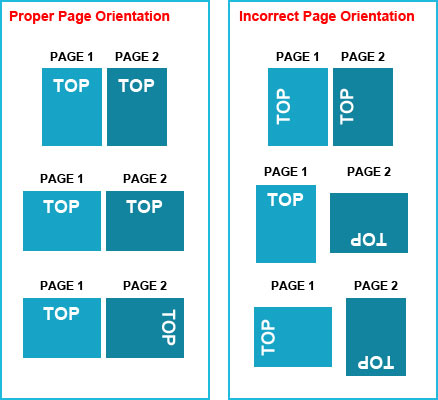

File Orientation Guide

Learn MoreHow to set up proper orientation for your files

File Orientation refers to the orientation of the artwork files submitted. Ensure that they are submitted to back up properly to produce the intended result.

Flat Artwork (Postcards, Flyers etc.)

How To Set Up Your Files

Learn MoreLearn how to set up your files the right way.

General File Preparation Guidelines

- Download our guides to ensure a more optimal print result.

- Be sure to DELETE any hidden layers that are not intended to print (ie: setup guide layers or other hidden artwork layers) to ensure no risk of them appearing on the final print.

- Each job (including multiple paged projects) must be submitted as a single PDF file. Ensure that all pages are the same size.

- Files must be submitted with proper orientation to ensure proper back up. Please review the File Orientation Guides carefully in the File Prep tabs for your particular product.

- It is best to try to avoid using borders in your design. If a border is too close to the trim, the trim may be slightly off-center.

- File must consist of 1/8" bleed and all important art and text must be within the safety margin. The more safety margin the better (to avoid awkwardly close trims or having critical elements from getting cut off).

- Ensure that your PDF is high res and that all images are CMYK at 300 DPI.

- Black text/type should have the following values: C0, M0, Y0, K100.

Larger areas of black coverage should be C:30/M:20/Y:20/K:100 to get a deep richer black. (For more info, click here) - Embed or outline all fonts.

- For best colour results, supply a CMYK only file (unless your product type specifically requires RGB color mode or specifically requires you to supply PMS colors).

While SinaLite maintains strict quality standards, minor shifts in printing are possible. Thin or small white text knocked out from a rich black background is prone to printing issues, such as color bleeding, filling in, and poor readability due to slight misregistration. We recommend preparing files with the following tips in mind.

-

Use C30 M20 Y20 K100 for Rich Black

Use this recommended rich black formula to minimize oversaturation and registration problems. Avoid heavier CMYK builds like C60 M60 Y60 K100, which can increase color shift risks.

-

Thicken White Knockout Text

Increase the thickness of white text knockouts to prevent them from filling in or becoming unreadable.

- Recommended minimum line weight: 0.75pt

- Recommended minimum font size: 8pt

-

Apply Swelling

Swelling (slightly enlarging knockout areas) compensates for minor ink spread on the press. Slightly increasing the size of the white knockout text can help maintain crispness after printing.

Common Issues

Learn MoreHow to avoid common file issues

How to ensure proper orientation/backup

Why bleed is necessary for print

Why you should avoid border designs

How to set up dielines

Why safety margins are necessary for print

How to create transparent PNG files

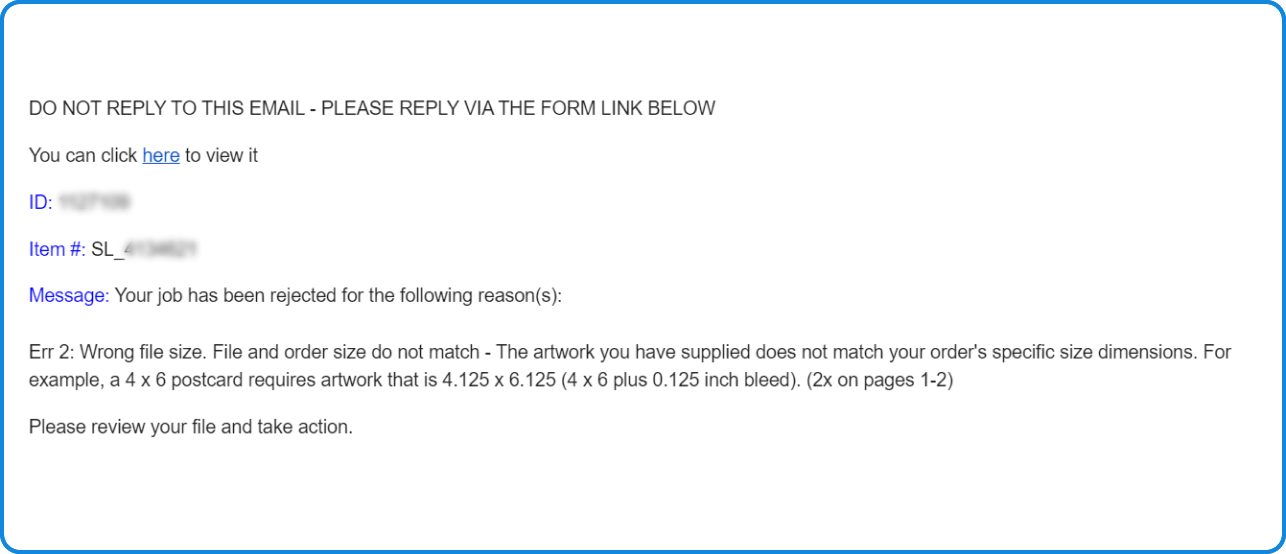

Upon placing an order, you will receive a confirmation email stating that the order has been successfully placed.

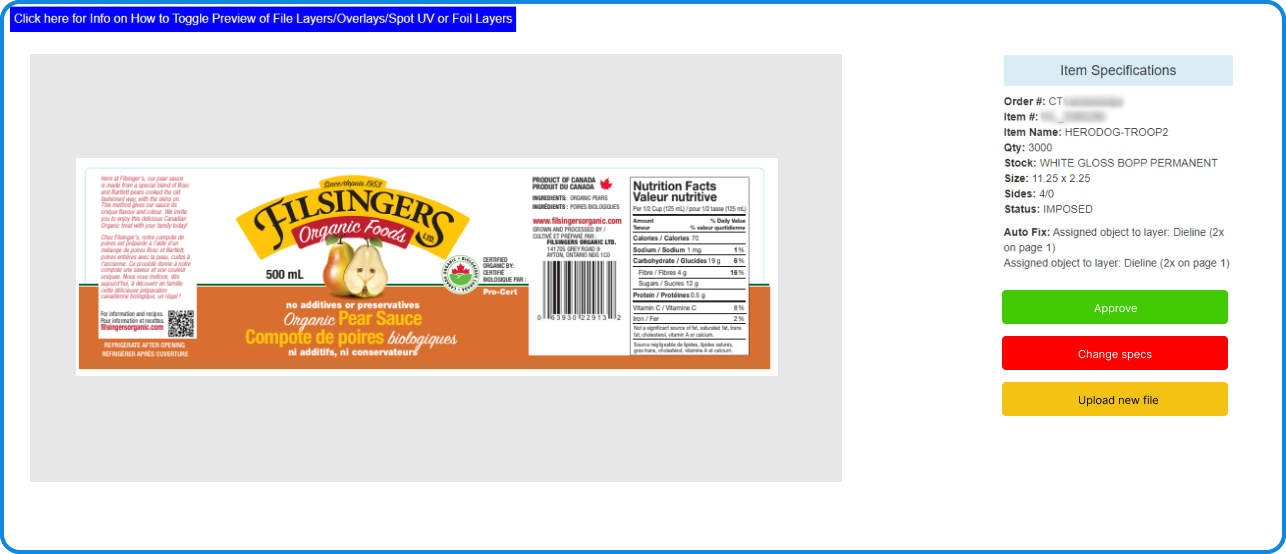

After processing your order, our prepress team will review your artwork and run automated checks to ensure its print readiness. Once completed, our automated system will send you a link. This link allows you to approve the file to proceed, make changes to the file, or put the order on hold.

Please note that you are responsible for final proof and layout approval prior to the printing process, so make sure you check carefully for language and grammar, graphics, bleeds, damaged fonts, overprinting, form fields, and files not built to template or page order prior to approving your file.

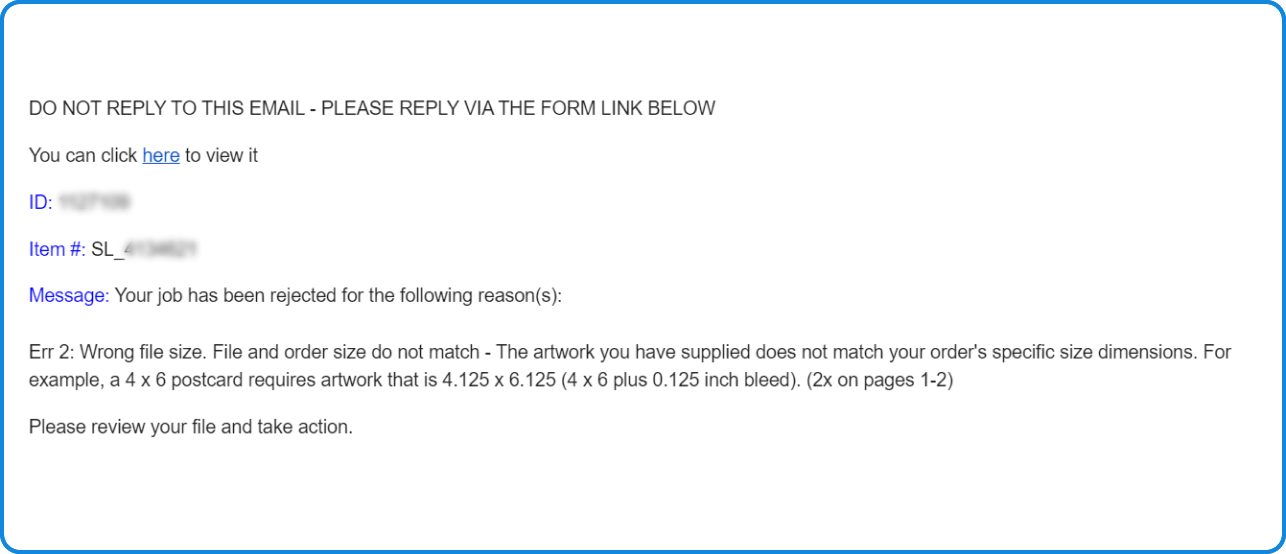

In the event that your order has been rejected, you will receive an email notifying you of the rejection. You'll have the option to upload new artwork, place the order on hold, or cancel the order.

FDA 21 CFR 177.1630 compliant

PE:FDA 21 CFR 175.105, 175.300(b)(3)(xxx), 175.320(b)3iii, 176.180, 176.210, 177.1200 , 177.1210, 177.1350, 177.1520(a)(2)(i), 177.1520(a)(3)(i), 177.1520(a)(3)(i)(a)(2) , 177.1520(a)(3)(i)(c)(1), 177.1520(b), 177.1520(c)2.1, 3.1a, 178.2010(b) , 178.3120, 178.3297(e), 178.3400, 178.3750, 178.3860, 179.45 , 181.28, 181.29, FCN 1753

Conditions of Use:Conditions of Use B - H, as described in Table 2 of 21 CFR 176.170(c) For use in contact with nonalcoholic food. Not for use in contact with infant formula and breast milk but may be used in repeat use articles for feeding infant formula and human milk as well as packaging of powdered infant formula.

Create a Support Ticket

Create a Support Ticket Call 1-866-899-2499

Call 1-866-899-2499 Chat with an Agent

Chat with an Agent Go to Support Center

Go to Support Center

Validate your login