What does matte finish mean? Is spot varnish the same as spot UV? Can you write on laminated paper?

These are common questions asked by customers buying print. Print sellers know the answers, but sometimes it can be a challenge to explain coatings to customers who know nothing about print. Showing samples is a great way to help them understand, but having all samples with you at all times may not be possible. Besides, your customers may want to get an idea of the bigger picture before they make their decision.

To help you explain popular types of coatings in the clearest manner possible, we’ve provided a helpful guide with diagrams. Use this to clarify terms with your clients and win more sales.

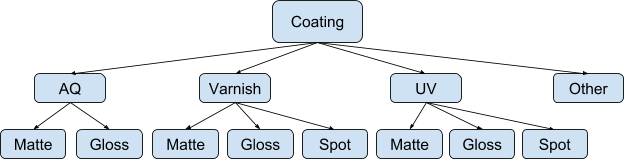

Types of Coating

AQ (Aqueous) Coating

|

Varnish

|

UV (Ultraviolet) Coating

|

Other

|

A word of warning: Coating a product may increase the likelihood of cracking when it’s scored or folded.

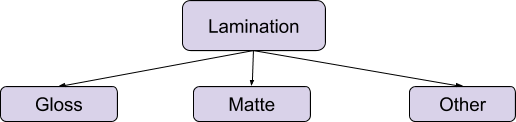

Lamination

Gloss Lamination

|

Matte Lamination

|

Other

|

Terms with Nonstandard Usage

The terms below are used differently by each printer to describe their products. For example, “matte finish” could refer to no coating for one printer and matte lamination for another.

Make sure your customers know what to expect if you use these terms to describe your products. Likewise, if you print with an outsource supplier, make sure you understand what they mean when they use these terms.

Tip: You don’t need to call your products the same name as your supplier calls theirs, but make sure you don’t accidentally confuse yourself when you order from them!

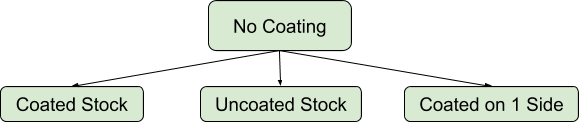

No Coating

Be careful. No coating mainly refers to products that don’t get coated after printing. Whether the stock you’re printing on is already coated or not is a different matter.

Coated Stock

|

Uncoated Stock

|

Coated on 1 Side

|

Another word of warning: Some stocks can’t be written on even if they’re uncoated (e.g. plastic).

Combinations

Combining coatings and laminations can create special effects. For example, a business card with matte lamination and spot uv will allow certain parts of the artwork to stand out more than usual.

Tip: New coatings and changes to existing ones are continuously developing. Educate yourself so that you know what you can offer.

Conclusion

Does this sound like a lot of explaining? Would you rather just use a sample? SinaLite has a vast selection of coatings along with custom job options. Simply sign up and request a free sample kit package.

It’s always good to offer your clients many types of coatings. This way you can be a one-stop shop for all their needs. We invite you to partner with SinaLite so that you can offer more choices to your clients and expand your business. After all, helping printers like you is what we do.

Learn more: Natural Remedies for Potency: Boost Your Vitality Naturally

Great article – can we get a PDF to show our customers and perhaps to personalize?

Hi Lisa, thanks for the great suggestion! We’ll pass the suggestion along to our team.

Good job on explanation.

if it’s free what is $11+ charge about?

Hi Brenda, thanks for reaching out with your question. When you first sign up, you can request a free sample package by writing in to [email protected]. After that, you would be able to order more if you’d like for the price listed on our website. Hope that helps!