Picture this. A client has just sent you a beautifully designed file, which you proceed to print right away. It’s only when the product comes off the press that you realize something has gone terribly wrong. Images have shifted, some have disappeared altogether, and colors are dull. The printed product looks nothing like their file. Panic ensues.

Chances are your client’s file probably contained a mixture of color modes and complex objects. But could such small file issues really create a printing disaster of this magnitude?

Yes. Yes they can.

No printer wants to end up in this situation, but the good news is that these printing mishaps are largely avoidable when files are built correctly with the right color mode, overprint settings, and orientation, as well as free of unnecessary or unprintable elements.

So whether you’ve been in hot water before or never intend to get that far, here are 5 dangerous file issues that could seriously impact print results, and solutions to overcome them.

Things to Check to Avoid File Issues

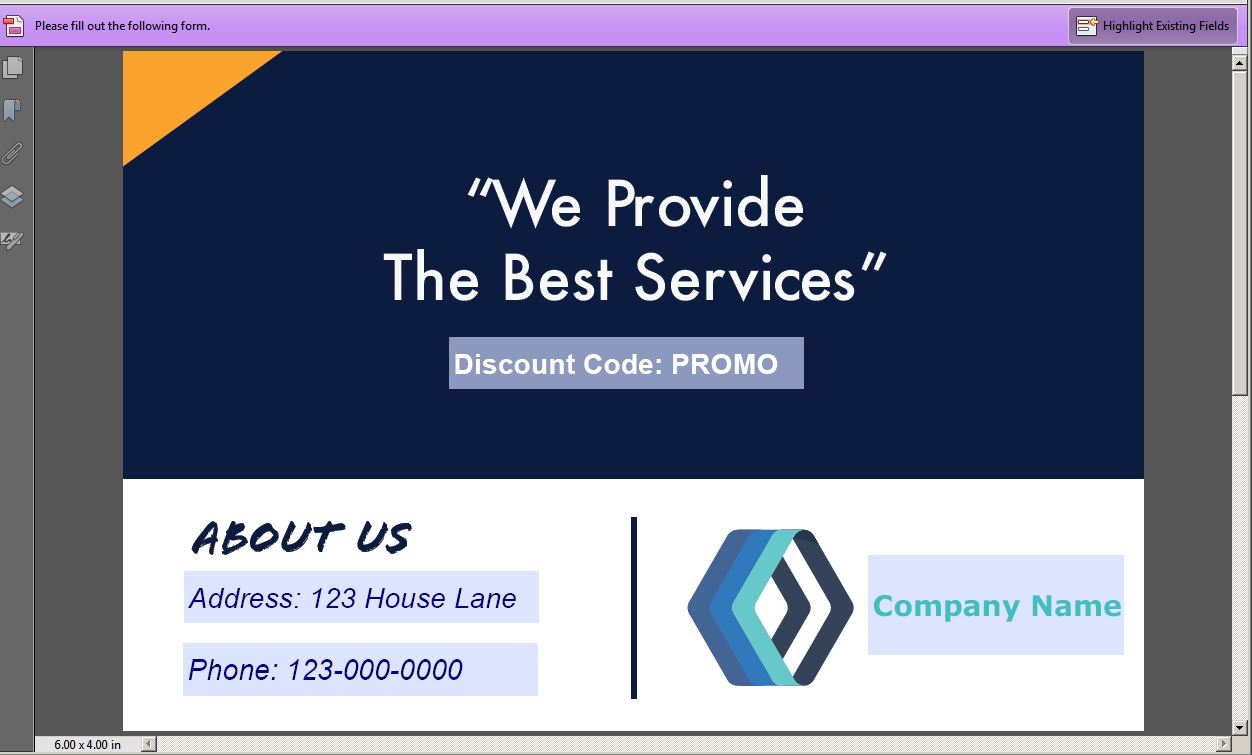

1. Form Field Data

Trying to print form field data can result in missing text or images – often those that are the most important to your client – making this one of the most dangerous file issues for print. Imagine form field data like audio clips on a print file – they’re not printable parts of the PDF. The same goes for comments and annotations.

Solution: The good news is that this file issue is easily avoidable. Flatten all form field data. This converts them into printable parts of the file. Alternatively, you can manually add the text and images onto your file and then delete the form fields, comments, or annotations.

2. Color Modes

Providing non-CMYK color modes can result in not only colors changing but images completely disappearing. When your software converts colors to make them printable, it may not produce the result your clients wanted. This is especially dangerous when mixed color modes interact with each other in unexpected ways during conversion.

Solution: Encourage your clients to build their file in CMYK only in its native application. If the file requires spot colors, make sure your press (or your outsource printer’s press) is able to work with them without conversion. If you have to convert a client’s artwork, try a few different conversions first, as not all are equal.

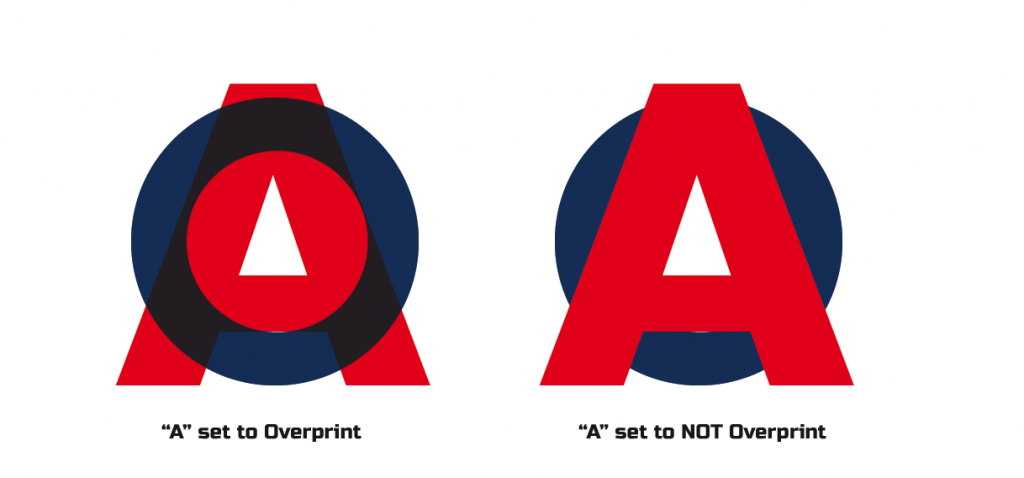

3. Overprint Settings

Incorrect overprint settings can make objects look overlapped when they shouldn’t or vice versa. It can also make poor registration more obvious and in some cases artwork can even seem to disappear.

Solution: Setting overprint correctly will depend on the design and the effect that your client wants to achieve, so there isn’t one rule to cover everything, but be sure to check the file in overprint preview, or with “simulate overprinting” turned on. Pay particular attention to black and white objects, and to both fill and stroke. If you outsource your printing, check with your printer’s file setup guides, especially when building files with white ink.

4. Orientation

Orientation can be complicated on products that require folding. Files with orientations that are not built correctly for the workflow can result in artwork printing upside down from what your client intended.

Solution: Pull a mock-up proof and fold it to make sure it backs up as your customer intends. Make sure you flip it on the correct edge to match your workflow. If you outsource your printing, check your print supplier’s setup guides.

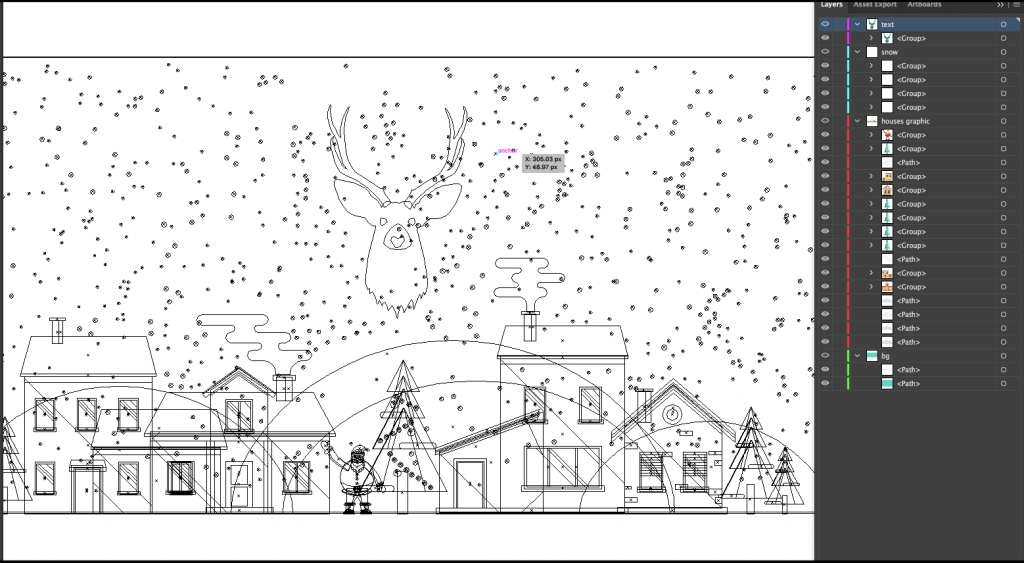

5. File Complexity

The more complex your file is and the more files on one press run, the higher the chance of RIP errors. Artwork or type may drop off, shift, or get distorted on not just one but multiple jobs on that press run because a file contains so many objects that the RIP system has trouble processing them.

Solution: Encourage clients to simplify files that look like they may be too complex for your RIP software. Possible methods include rasterizing the most complex parts of the design, combining objects, simplifying paths, or flattening transparencies.

Conclusion

Now that you’ve familiarized yourself with some of the most common yet dangerous file issues, we encourage you to bookmark this blog article to use when you’re reviewing client files. Don’t forget to share this article with your customers too. This way, not only will they provide you with better files to print, but they’ll also see you as a trusted, educated printer who knows best practices.

Please share with us in the comments below any other file setup tips that you use for great print results!